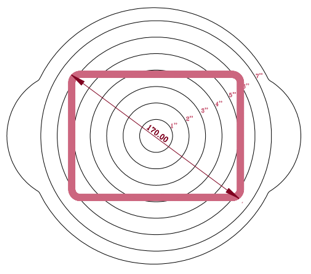

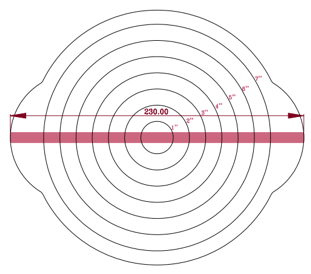

Alumac has 3 extrusion presses (600, 1460 and 1800 US Ton) which enable us to extrude 4”, 6” and 7” aluminium billets respectively. With our largest 7" extrusion press, we can extrude up to 170mm CCD for hollow profiles and up to 230mm in width for flat profiles.

Max. 170mm CCD for Hollow Profile

Max. 230mm width Flat Profile

An extrusion die is a thick steel disk with a shaped opening to allow aluminium to flow through, producing a specific cross-sectional profile.

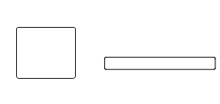

Solid Die – Enables the extrusion of an aluminium profile with no enclosed voids, such as

Hollow Die – Enables the extrusion of an aluminium profile with enclosed voids, such as

Semi-hollow Die - Enables the extrusion of an aluminium profile with deep gaps or opening with high tongue ratios, such as

Pure aluminium is made up of only aluminium element, the atomic number 13 with the chemical symbol of Al in the periodic table. It appears as a silvery-white soft metal.

Aluminium alloys are mixtures of pure aluminium with other elements to enhance the mechanical and chemical properties of the metal, tailored for different applications.

Such enhancements include the increase in strength, workability, corrosion resistance and electrical conductivity.

Such elements that create an aluminium alloy include silicon, iron, magnesium, copper, manganese and chromium.

Yes. The choice of aluminium alloys depends on a range of factors, which includes product application, strength requirements, and surface finishing requirements.

We provide 1000 and 6000 series of aluminium extrusion grade alloys, of which we primarily use extrusion grades 1050, 1070, 6060, 6061, 6063 and 6082 to create your profiles.

|

Aluminium Alloy |

Application |

|

1050 |

It is a high purity non-heat treatable alloy with 99.50% of aluminium content. Used especially in electrical fields (e.g.: busbar) which require the highest available electrical conductivity performance. |

|

1070 |

It is a high purity non-heat treatable alloy with 99.70% of aluminium content. Used especially in electrical fields (e.g.: busbar) which require the highest available electrical conductivity performance. |

|

6060 |

It is a heat treatable alloy with very good corrosion resistance and weldability. It is an ideal alloy for every complex cross section and has a very good anodizing response. Widely used in architectural applications, curtain walls, railings and fences. |

|

6061 |

Ideal for structural applications as it offers higher strength properties. It is widely used in transportation components, marine fittings, machinery and equipment and more. |

|

6063 |

It is a medium strength alloy which commonly used for architectural applications including door/ window frames, sign frames, recreation equipment, truck frames, heat sinks, electronic parts and etc. It has a good surface finish and can be easily anodised. |

|

6082 |

It has excellent corrosion resistance and the highest strength of the 6000 series structural alloys. It has good weldability and is commonly used in marine applications. |

For more information, click here to know more about the Chemical Composition Limits of our alloys. If you require any assistance in selecting your aluminium extrusion grade for your profile's applications, feel free to contact us.

Temper, which is the hardness and strength imparted to the metal by mechanical or thermal treatment.

1000 aluminium extrusion grade series are cold-worked for strength enhancement.

6000 aluminium extrusion grade series of alloys are heat-treatable to attain their maximum strength. Alumac controls this process via an ageing oven.

|

Typical Extrusion Tempers |

Description |

Details |

|

F |

As Fabricated |

There is no special control over thermal condition and there are no mechanical properties limits. |

|

T1 |

Thermally Treated |

Cooled from an elevated temperature and naturally aged. |

|

T4 |

Thermally Treated |

Solution heat-treated and naturally aged |

|

T5 |

Thermally Treated |

Cooled from an elevated temperature and artificially aged. |

|

T6 |

Thermally Treated |

Solution heat-treated and artificially aged. |

For additional information, including the performance parameters on different alloys with different tempers, click here.

The aluminium extrusions we supply meet tolerances outlined by Aluminium Association (AA) standard. You can check out the Quality Standards here.

However, we strive to drive our extrusions further than the AA standard.

If you have specific or increased tolerance requirements, kindly contact us as we have a technical engineering team to discuss with you how we can help you.

We are able to deliver extruded lengths of up to 12 metres, subject to your technical needs and requirements.

We can provide the following surface finishings that would suit your needs:

- Anodising

- Metallic Anodising

- Powder Coating

- PVDF Coating

- Hairline Surface

- Wood Grain

Alumac specialises in bespoke designs, and co-engineered with you, the customer, for better solutions that suit your applications. As such, we are able to extrude aluminium profiles according to your designs to the exact specifications.

However, we can access a full range of standard extruded aluminium profiles on behalf of our customers.

Quality - We Walk The Talk, being one of our brand promises. We are fully ISO9001:2015 certified to assure our customers always receive the very best.

We utilize Digital Quality Management in our inspection procedure. An example of which, we employ Bluetooth Calliper, Video Measurement Scanner, Image Dimension Measurement System to cover non-destructive and destructive dimensional inspection. In addition, we also utilize other measurement tools to test your profiles’ electrical conductivity and surface roughness of the extrusion profiles. Click here to know more.

Alumac prides itself with our Quality Check Points (QCPs) being set for every production process. All quality personnel are committed to focus on each QCP in each production process. Click here to know more.

Yes. We are able to provide you with a 3D printed sample for your fitting and evaluation purposes as we co-engineer with you on your designs.

|

Stage |

Steps |

|

Inquiry Stage |

(1) Design Review: - Send us your designs or samples and we will provide you a free CAD design support while identifying improvement opportunities, fulfilling one of our 3 brand promises, co-engineering for better solutions. |

|

(2) 3D Printing Sample: - An industrial standard 3D printed sample can be provided for your fitting and evaluation purposes. |

|

|

Service Stage |

(3) Die Development: - High precision die fabrications take 3 weeks upon design approval. The completed die will undergo a free trial run, which its samples along with a First Article Report will be provided 1 week later. |

|

(4) Online Production Tracking: - Upon approval of the sample, full production can be started. During a full production run, regular updates will be provided until delivery. |

|

|

After-Purchase |

(5) Customer Review: - We value every collaborative effort we make with our customers. A full review on your experience working with us would be valuable for us to service you better. |

Let’s collaborate today! Working together, we will be STRONGER TOGETHER.

Alumac takes an average of 4-6 weeks, depending on the processes involved to meet your specifications.

Of course! Alumac will always welcome our prospective customers to see what we do first hand.

We strongly believe that our facilities and services are testaments to being the best aluminium profiles provider. Contact us to make an appointment.

Yes. Our products are compliant to the Restriction of Hazardous Substances (RoHS) Directive and Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) Regulations.

One of Alumac's core values is CARE, to genuinely care for our people, product and our planet.

A great example would be our anodising processes using Alufinish chemicals. They are imported directly from Germany for both purposes of complying with RoHS Directive and REACH Regulations while without compromising on delivering high quality products to our customers.